Part 2: Tools and Materials. July 22-24

After deciding to build the cocktail maker, I did what any reasonable person would do: opened twenty tabs, dove into forums, watched way too many YouTube tutorials, and got lost in an endless rabbit hole of components and builds.. This part of the process was honestly fun. Between the researching electronics, tubing, pumps, and all the basic tools I didn’t own yet, I quickly found myself deep in “DIY cocktail machine starter pack” territory.

Things I Already Had

Luckily, I wasn’t starting from absolute zero. I had a few leftover parts from past mini-projects:

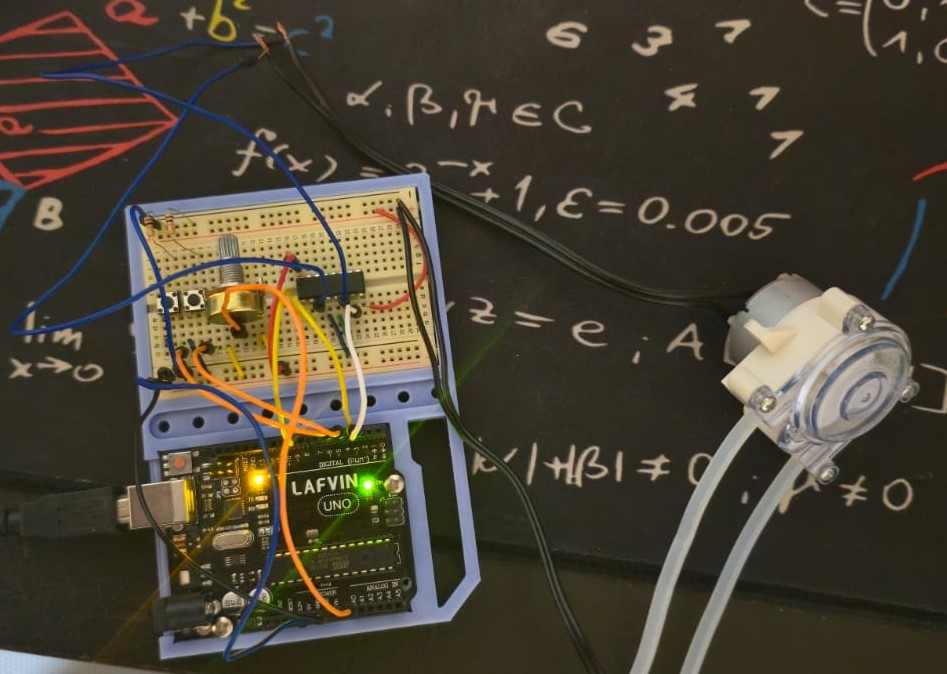

- Arduino Uno – A solid board for prototyping. I might switch to something else later — maybe a Raspberry Pi if I want more power or connectivity.

- Breadboard – Already broken in from previous experiments.

- Jumper wires – Always useful for quick testing on the breadboard.

- AC cable and plug (I think) – Could be handy for hooking up a wall adapter or power supply.

- Some loose copper wires – Enough to get the prototype wired up and moving.

Not enough to build the machine, but enough to start messing around.

Things I Needed to Order

I split the shopping list into two parts: the tools I needed to properly work with electronics, and the prototype components I’d need to start building the actual cocktail maker. I realized I needed some basic tools to get started:

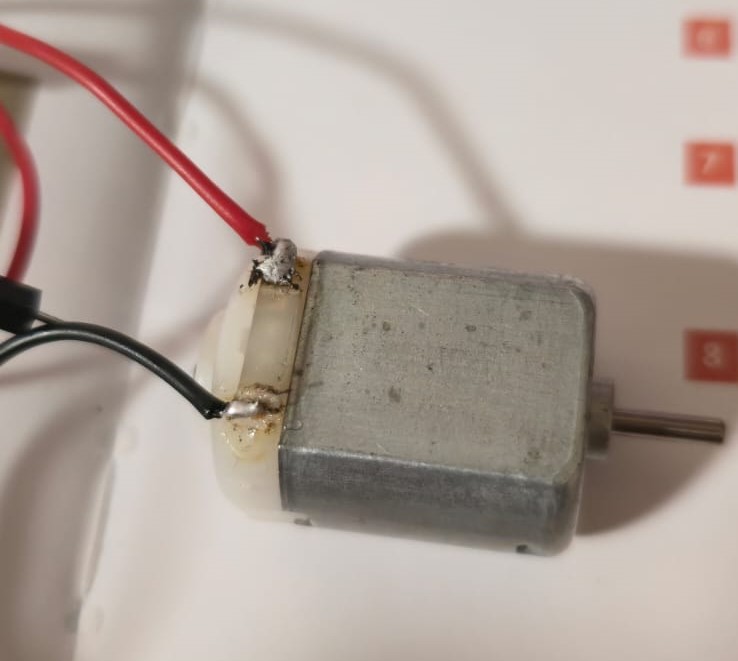

- Soldering iron – Essential for connecting components.

- Solder – Leaded, because I wanted my first joints to flow nicely.

- Flush cutters – For trimming component leads cleanly and cutting wires to size.

- Multimeter – For checking voltage, resistance, and current… or so I hoped.

Prototype Components:

- Two 12V 500ml peristaltic pumps – The core for moving liquids precisely.

- 4-channel relay module – To control the pumps safely with the microcontroller.

- 0.96-inch OLED display – Honestly, I saw it while browsing and couldn’t resist. It was too cheap to pass up.

- 12V 10A power supply – Plenty of juice for the pumps and electronics.

The Multimeter Incident

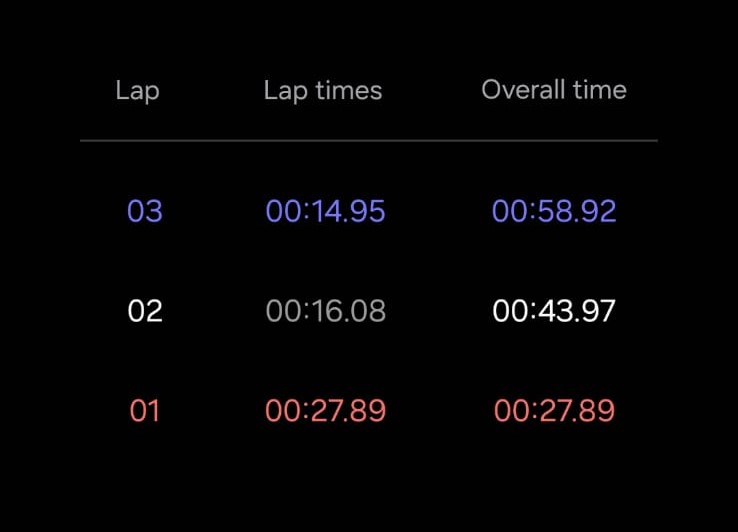

Within just three hours of the tool kit arriving, I managed to mess something up.

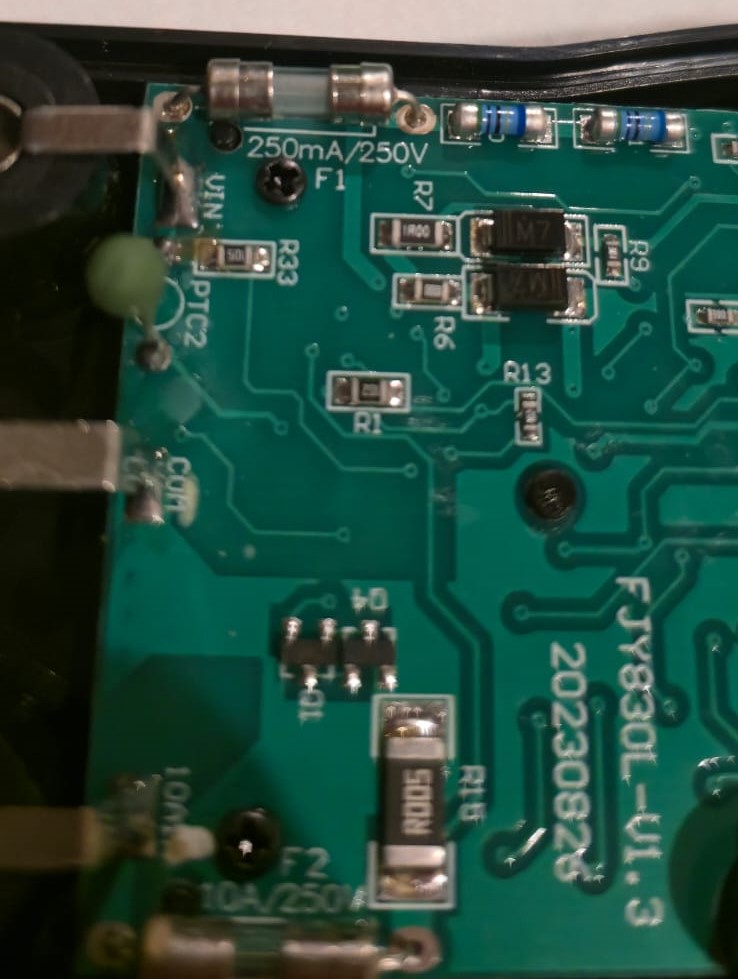

I tried measuring current without switching the probes properly and instantly blew the fuse inside the multimeter. Voltage readings stopped working, and only resistance mode still showed signs of life.

When I opened it up and saw the tiny glass fuse snapped in half, I laughed it off. If you haven’t blown a multimeter fuse yet, are you even doing electronics?

Other Early Moments

The day after ordering, the soldering iron and multimeter arrived. While waiting, I found an AC cable and plug.